48V vs. 72V Ebike Batteries: The Ultimate B2B Guide to Inventory, Compliance, and Performance

In the rapidly evolving landscape of electric mobility, the "Voltage War" is a strategic conversation every B2B product manager and distributor faces. B2C customers are demanding higher metrics: faster acceleration, steeper hill-climbing torque, and the thrill of a 72V ebike.

However, for OEM integrators and dealers, blindly pursuing high voltage creates liability. It introduces complexities in inventory SKU management, battery safety compliance (UL standards), and import classifications.

At Poleejiek, we prioritize liability management alongside performance. This technical guide analyzes the industry-standard 48V architecture against high-performance 72V systems, providing the data you need to make informed procurement decisions.

The Core Dilemma: Market Volume vs. Niche Performance

Distributors must balance two distinct inventory categories:

- Volume SKU (48V): Mass market, street-legal, lower liability.

- Niche SKU (72V): Enthusiast market, 50+ mph electric bikes, higher margin but higher regulatory scrutiny.

48V Systems: The Global "Gold Standard" for Compliance

Despite the hype around high voltage, 48V remains the backbone of the industry. For 80% of B2B dealers, this is the safest inventory staple due to regulatory alignment.

48V systems are optimized to comply with:

- USA: Class 1, 2, & 3 definitions (Max 750W, 20-28mph) under CPSC 16 CFR Part 1512.

- EU: EN 15194:2017 standards for EPACs (250W, 25km/h), where 48V is the upper limit for "Low Voltage" safety exemptions in many component certifications.

B2B Strategic Advantages of 48V

- Supply Chain Stability: 48V components (controllers, BMS, chargers) have a mature supply chain. Replacement parts are universal, significantly reducing your after-sales support burden compared to proprietary 72V parts.

- Cost Efficiency: A 48V 15Ah pack uses ~52 cells (13S4P), whereas a 72V 15Ah pack requires ~80 cells (20S4P). This 35% reduction in cell count allows for a competitive MSRP, driving volume sales.

72V Systems: High Performance & Thermal Efficiency

The 72V ebike is the "Supercar" of your showroom. It is essential for capturing the electric dirt bike demographic, but it requires a "Motor Vehicle" sales approach.

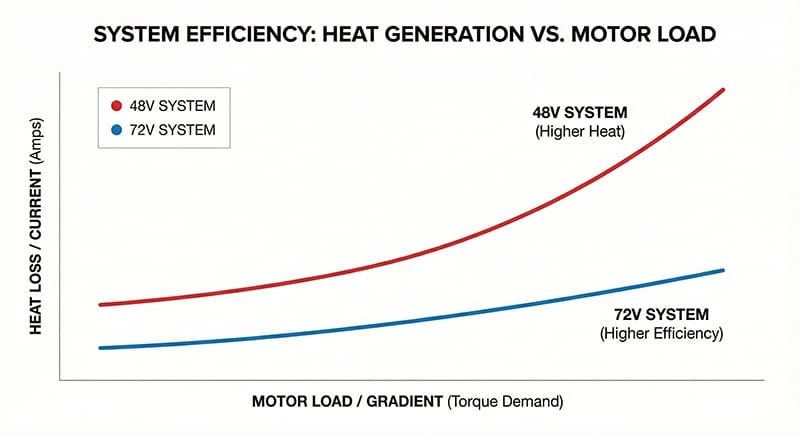

Engineering Deep Dive: The Efficiency Advantage

Why choose 72V? It isn't just about top speed; it's about Thermal Efficiency under load.

Let's look at a 1500W hill-climbing scenario. To produce 1500 Watts of power, the controller draws current based on the formula P = V × I.

| System Voltage | Current Draw (Amps) | Heat Generation Risk* |

|---|---|---|

| 48V System | 31.25 Amps | High (More resistive heat loss) |

| 72V System | 20.83 Amps | Low (33% Less Current) |

In the EU, 72V bikes almost always fall under Regulation (EU) No 168/2013 (L1e-B Moped). Distributors must ensure these units have CoC (Certificate of Conformity) and type approval, or risk customs seizure.

Poleejiek’s Safety Protocol: Mitigating Lithium Risk

Whether you choose 48V volume sellers or 72V performance flagships, Safety is the new Currency. With NYC Local Law 39 and potential EU battery regulations, cheap packs are a liability time bomb.

At Poleejiek, we mitigate distributor risk through a rigorous 3-step protocol:

1. Tier-1 Cell Sourcing (No Generic Cells)

We exclusively source UL 1642 recognized cells from Tier-1 manufacturers (Samsung SDI, LG Chem, Panasonic). We reject "re-wrapped" or "Grade B" cells that plague the budget market. Consistent internal resistance ensures the pack remains balanced over 800+ charge cycles.

2. Intelligent BMS with Redundancy

Our proprietary BMS is engineered to meet UL 2271 design standards.

- Active Monitoring: For 72V (20S) packs, we use dual-temperature probes to monitor heat at both the cell center and the BMS MOSFETs.

- Short Circuit Protection: Hardware-level disconnects activate within microseconds of a short, preventing thermal runaway.

3. Certification Readiness

We assist our OEM partners in obtaining full UL 2271 certification for their custom battery packs, streamlining your entry into regulated markets like New York City and France.

Conclusion: Sourcing for Your Business Model

Quick Procurement Decision Matrix

- Choose 48V If: You target urban commuters, delivery fleets, or require Class 1/2/3 compliance (USA) / EN 15194 (EU). Focus: Volume & Safety.

- Choose 72V If: You target off-road sports, hunting, or private land use. You are prepared to handle "Moped/Motorcycle" classifications. Focus: Performance & Margin.

Secure Your Supply Chain

Liability stops with the importer. Ensure your fleet meets 2025 safety standards.

Download the Poleejiek OEM Battery Safety Spec Sheet. It details our thermal testing data, cell sourcing list, and BMS protection logic for both 48V and 72V architectures.